|

#1

January 23rd, 2016, 04:47 PM

| |||

| |||

| Process in KMML

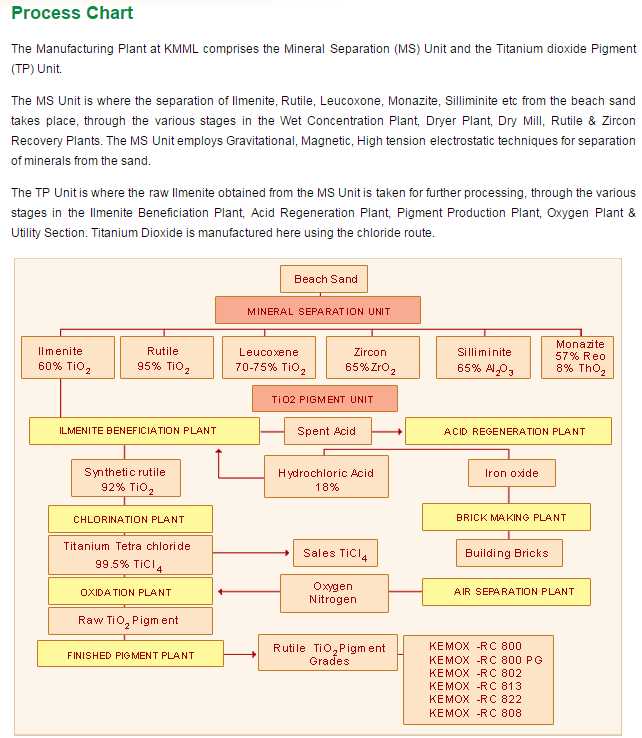

I want to get information about the Process in Kerala Minerals and Metals Limited. So here can you provide me information about the process? If you want to get information about the Process in Kerala Minerals and Metals Limited, then here I am telling you about it, as you want. The Process The Kerala Minerals and Metals Ltd is the world’s first fully integrated Titanium Dioxide Plant. Kerala Minerals and Metals Ltd is also India’s first and only manufacturer of Rutile Grade Titanium dioxide by chloride process. The Process in Brief: Titanium dioxide, also referred to as Titania, is a substance as old as the earth itself. Titanium dioxide is readily mined in its purest form from beach sand. The beaches of Sankarmangalam and nearby areas in Kollam are inextricably intertwined with the history of this substance and Kerala Minerals and Metals Ltd. Dr. Schomberg, a German Scientist, discovered in 1909 traces of monazite in the sand flakes on the imported coir from Sankaramangalam. The beaches with a wealth of rare earth minerals became the centre of scientific attraction. Kerala Minerals and Metals Ltd is the world’s first fully integrated Titanium dioxide plant. Titanium Dioxide is essentially harvested from sea. The Mineral Separation Unit (MS Unit) of Kerala Minerals and Metals Ltd is engaged in the separation of Ilmenite, Rutile, Leucoxone, Monazite, Silliminite etc from the beach sand. The MS Unit employs Gravitational, Magnetic & High Tension Electrostatic Techniques for separation of minerals from the sand. Raw Ilmenite is chemically processed to remove impurities such as iron, leaving the pure, white pigment available for use. Kerala Minerals and Metals Ltd is India’s first and only manufacturer of Rutile Grade Titanium dioxide by chloride process. The chloride process produces Titanium Dioxide TiO2 products by reacting titanium ores with chlorine gas. The chlorides of impurity metals are removed from Titanium Tetra Chloride (TiCl4) through various processes to complete the recovery of TiCl4. It is further purified by distillation to obtain pure Titanium Tetra Chloride(TiCl4) in the liquid form which is stored in storage vessels. Titanium Tetra Chloride (TiCl4) is vaporized, pre heated and oxidized with oxygen in the Oxidation Plant to produce raw Titanium Dioxide at a high temperature. Beneficiated Ilmenite (BI) is the raw material for the Pigment Production Plant. Beneficiated Ilmenite (BI) from Ilmenite Beneficiation Plant is chlorinated in the Chlorination Plant to produce Titanium Tetra Chloride (Tickle). Chlorine reacts with Titanium Dioxide and other metallic oxide impurities in BI in the presence of petroleum coke at a temperature of 9000C in a fluidised bed chlorinator to produce chlorides of Titanium and other impurity metals. The raw Titanium Dioxide is then classified and surface treated with various chemicals, filtered and washed to remove the salts, sent to the dryer and then to the microniser, in the Pigment Surface Treatment & Finishing Plant. The Titanium Dioxide pigment (in powder form) is subsequently packed. The plant uses recycling and regeneration methods at various levels of processing, including acid regeneration, which ensures negligent pollution. Responsible harvesting from the seas reaffirms our commitment to the environment. Sponge Production Process The Technology being adopted for production of titanium sponge is a batch process based on the Kroll process. The titanium sponge plant is designed to produce 500 TPY of commercially pure Titanium sponge by the reduction and pyro-vacuum distillation of anhydrous TiCl4 with Magnesium Magnesio- Thermic Reduction of Titanium TetraChloride (TiCl4) into Titanium Sponge (Ti) and Magnesium Chloride i.e. MgCl2 TiCl4(g) +2Mg (l)=2MgCl2(l) +Ti(s) Purification of the sponge cake by Pyro-Vacuum distillation to remove lockedup magnesium and MgCl2. The main steps involved in the process are: 1.Purification of pigment grade tickle to metal grade 2.Magnesio-thermic reduction of tickle 3.High temperature vacuum distillation of Magnesium and Magnesium Chloride 4.Handling,grading and evaluation of titanium sponge Process Chart  Last edited by Neelurk; April 6th, 2020 at 02:16 PM. |